Our company offers a wide range of electric actuators aimed at automating industrial valves. In practice, there are indeed numerous types and kinds of valves, which can be divided into several groups depending on the nature of their operation, their use, and various technical or physical parameters. These parameters include the nominal diameter (DN), the maximum allowable pressure in the pipeline, the load/control torque, and the closing speed of the valve. Knowing all these parameters is essential for selecting the appropriate electric actuator to control our valve.

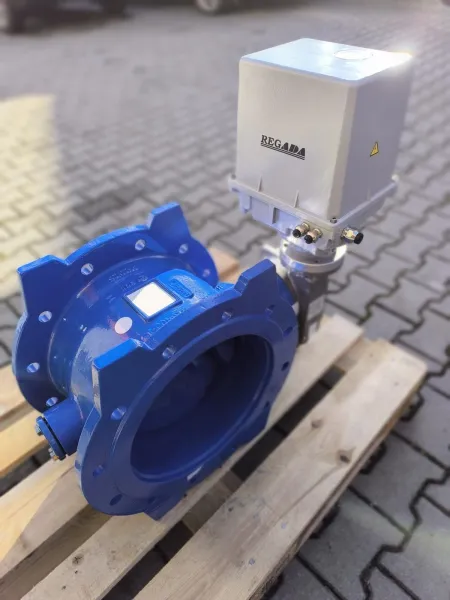

We are a company that also specializes in supplying so-called "assemblies," which is nothing more than the delivery of an electric actuator installed on the corresponding valve. We ship a fully set-up and aligned actuator along with the industrial valve according to the customer's requirements. The device is ready to be integrated into the pipeline system without the need for further adjustments.